amaea CSx: Your high-speed, low energy solution for cold stabilizing wine

Discover amaea CSx, amaea’s latest molecular filtration system, designed to continuously cold stabilize wine by rapidly and reliably removing potassium bitartrate (KHT) from wine.

70+% Energy

Savings

80%

Faster

Reliable Cold Stabilization

Energy and time savings relative to cream of tartar addition with 7-day refrigeration.

High-efficiency cold stabilization

Designed to optimize quality, reduce processing time, and minimize energy use, amaea CSx sets a new standard in cold stabilization delivering:

Reliable KHT Stability: Achieve potassium bitartrate (KHT) stability to user-specified conductivity levels, without compromising pH and wine quality.

Accelerated Processing: Instant precipitation reduces a 7-day cold stabilization process down to 1.

Sustainable & Cost-Effective: Integrated heat exchange technology saves energy costs.

Additive-Free: Functionalized crystals designed for reusability, helping retain yield and minimize waste streams.

Mobile, Scalable, Just-In-Time: Continuous, on-demand and mobile, designed for easy deployment, requiring minimal space and supporting infrastructure.

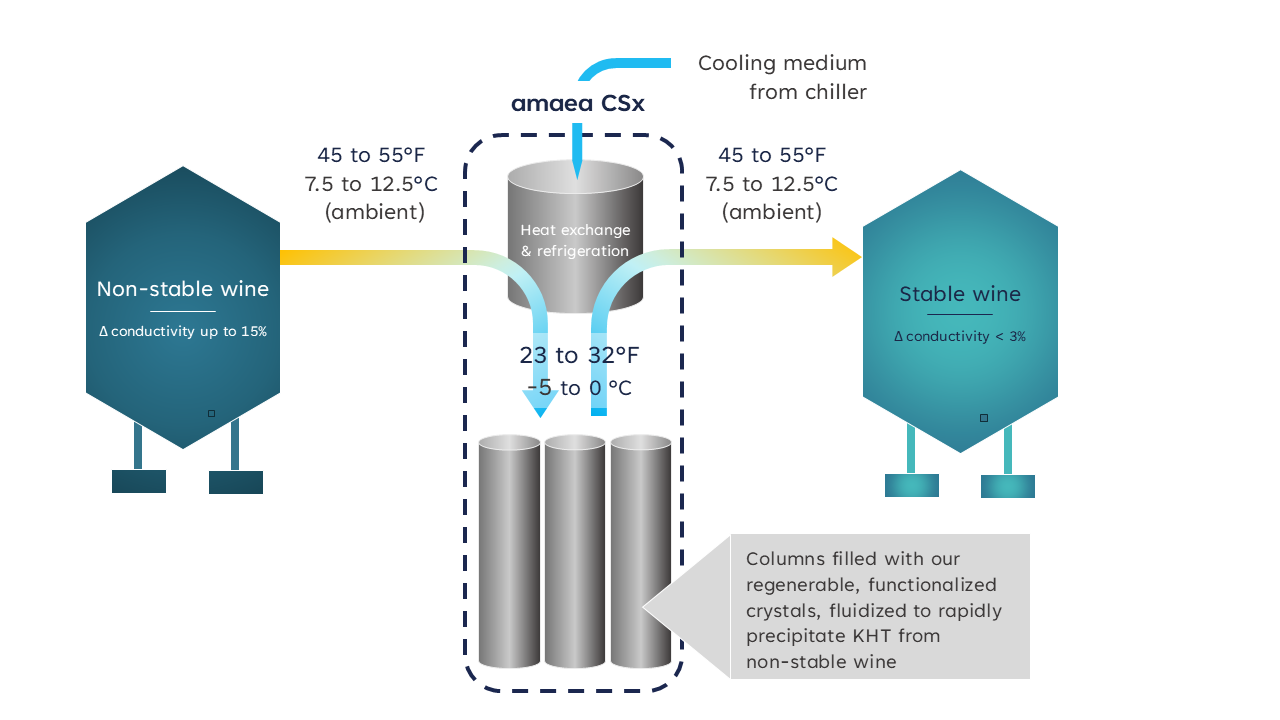

Non-stable wine is passed through amaea CSx at ambient temperature. Using heat-exchange technology, the wine is chilled and then passed through columns filled with regenerable, functionalized crystals, which are fluidized to rapidly precipitate potassium bitartrate from the wine to achieve the winery’s target conductivity. The stabilized wine is then returned to ambient temperature and sent to its selected destination.

How does amaea CSx work?

How does amaea CSx compare to other systems?

| Feature | amaea CSx | Refrigeration | Crystallization Inhibitors | Electrodialysis | Ion Exchange | Continuous Tartrate |

|---|---|---|---|---|---|---|

| Highly Energy Efficient | ✔︎ | ✔︎ | ✔︎ | |||

| Additive-free | ✔︎ | ✔︎ | ||||

| Preserves Wine pH | ✔︎ | ✔︎ | ✔︎ | ✔︎ | ||

| Good Yield Retention | ✔︎ | ✔︎ | ✔︎ | ✔︎ | ✔︎ | |

| Rapid Processing Time (Continuous) | ✔︎ | ✔︎ | ✔︎ | ✔︎ | ✔︎ | |

| Reliable Stability | ✔︎ | ✔︎ | ✔︎ | ✔︎ | ✔︎ | |

| Low Waste Stream | ✔︎ | ✔︎ | ✔︎ | ✔︎ | ||

| Mobile | ✔︎ | ✔︎ | ✔︎ | |||

| Cost Effective | ✔︎ | ✔︎ | ✔︎ |

Frequently asked questions about amaea CSx for cold stabilizing wine

-

amaea CSx is currently available through our service providers in New Zealand and the United States.

-

amaea CSx delivers rapid, continuous cold stabilization at processing rates over 10,000 L/hr due it’s scalable infrastructure. Compared with conventional in-tank methods, this reduces processing time by over 80%.

-

Yes. The target conductivity for cold stabilization varies by winery, as each has its own specifications. In general, cold stabilization requirements range from below 3% to 5%.

amaea CSx can be adjusted to meet each winery’s specific conductivity target by controlling the wine’s input temperature and flow rate.

-

No. amaea CSx is highly selective and is designed to achieve potassium bitartrate stability without impacting wine sensory or pH. This has been confirmed analytically and sensorially through tastings of treated wines.

-

amaea CSx is eluted and regenerated using water. The frequency of regeneration depends on the volume being processed however amaea estimates that when operating at full capacity the system will need to be eluted approximately twice a week.

Our service provider partners

We are proud to work alongside valued and trusted service providers to provide our molecular filtration services for you.

-

VA Filtration

VA Filtration is USA’s leading filtration technology experts with 18 years of experience in the wine industry.

-

Vintech Pacific

Vintech Pacific is a New Zealand owned and operated company, providing a range of innovative technology processes to the wine industry.

Want to find out more about amaea CSx?

Contact us today